AFTER FINDING SOME LONG STRIPS OF SCRAP TITANIUM, I DECIDED TO TAKE ON THE CHALLENGE OF LEARNING TO WELD THIS TEMPERAMENTAL MATERIAL. AFTER WEEKS OF RESEARCH, EXPERIMENTATION, AND STRATEGIC PRACTICE ON MY LIMITED MATERIAL, MY FINAL PRODUCT WAS A TITANIUM SHOT GLASS FORMED BY BEATING THE TITANIUM STRIP AND THEN WELDING IT TO A BASE CUT FROM THE SAME MATERIAL.

THIS WAS AN EXTREMELY CHALLENGING PROJECT BECAUSE THE WELDS HAD TO BE PERFORMED BETWEEN THE VERY UNEVEN HAMMERED SURFACES BETWEEN WHICH THERE WERE LARGE VARIATIONS IN THICKNESS AND GAP. SINCE I DID NOT HAVE ACCESS TO TITANIUM FILLER ROD, EVEN A TINY POINT OF BURNTHROUGH WOULD BE IRREPRABLE AND RUIN THE GLASS. THESE CHALLENGES FORCED ME TO BE FAR MORE EXACTING AND CONTROLLED IN MY PROCESS THAN I HAD BEEN WHILE PRACTICING, BUT AFTER A FEW HOURS, I HAD A WATERTIGHT PRODUCT!

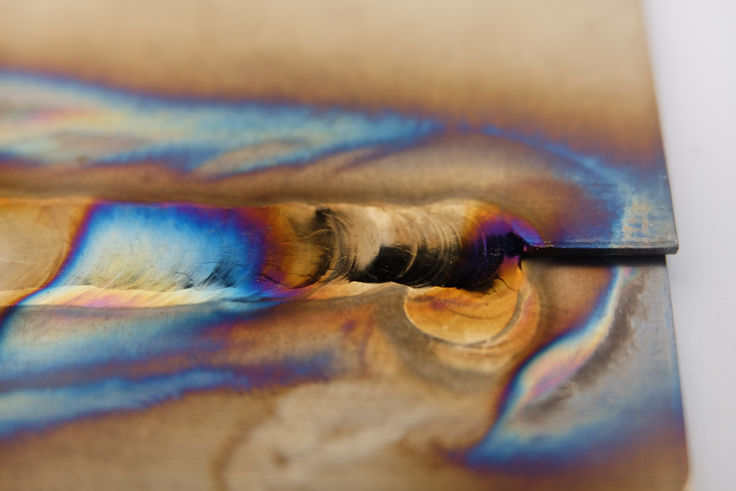

ONE OF THE HARDEST PARTS OF WELDING TITANIUM IS DEALING WITH THE OXIDES THAT BUILD UP RAPIDLY IF EVEN A SLIGHT AMOUNT OF OXYGEN WAS PRESENT. I WAS ABLE TO DESIGN A METHOD WHICH STOPPED OXIDE BUILDUP, AS CAN BE SEEN IN THE THIRD PICTURE. HOWEVER, IT INVOLVED USING AN EXTREMELY LARGE AMOUNT OF SHIELDING GAS. SINCE THE GAS IS EXPENSIVE AND MY WELDS ARE NOT STRUCTURAL, I ELECTED TO SAVE GAS AND ALLOW SOME OXIDE TO FORM, AS CAN BE SEEN BY THE RAINBOW COLORATION OF THE OTHER WELDS.